Products

Yapıser Profil Types

Yapıser CTP plate is a contemporary product developed to be used at all roof and facade coatings which need natural light. It is resistant against interior and exterior effects, appropriate to all climate conditions, and is not affected from chemical environments.

Appearance:

There are no surface defects on plates like notch, hole, breaking, indent, foreign material, air bubbles, regions with low polyester level and film problems which can affect resistance and usage of products.

Color:

Colored plates have homogenous appearance and does not show color difference.

Thickness:

Plate thickness are formed according to TSI norms regarding 15% tolerance at corrugated plates, 5% tolerance at flat plates.

Weight:

Plate production is done as appropriate to 5% tolerance in plate weight.

Length:

Plates are produced with +2,5/-2 cm tolerance for 0-5 meter, +5/-3 cm tolerance for 5-10 meters and +5/-3 cm tolerance for more than 10 meters according to customer demand. Regarding transportation conditions, corrugated plates can be produced up to 15 meters. Flat plates can be produced in demanded lengths as far as they are appropriate to form roller.

Packing:

Plates can be presented to market by packing or in bulk form. For packing customer’s demand is regarded and number of stacked plates is determined according to transportation conditions.

Width:

Final width of plates according to used profile is appropriate to the values determined in profile leafs unless a different demand comes from customer. Width tolerance is ±0,001 meter.

Pitch Interval:

Pitch intervals of plates are ± 2 mm as appropriate to used profiles and values in standards.

Pitch Height:

Pitch heights of plates are values appropriate to used profiles.

Pitch height tolerance:

±2 mm for <30 mm and ±3 mm for >30mm.

An increase in pitch heights + deviation values is normal when plate thickness increases (at thicknesses bigger from 3 mm).

Beneficial Area:

Beneficial areas of plates are values determined in their leaf. Tolerance is ±10 mm.

Label:

Labeling is done with inkjet system in order to follow after sales traceability.

There are no surface defects on plates like notch, hole, breaking, indent, foreign material, air bubbles, regions with low polyester level and film problems which can affect resistance and usage of products.

Color:

Colored plates have homogenous appearance and does not show color difference.

Thickness:

Plate thickness are formed according to TSI norms regarding 15% tolerance at corrugated plates, 5% tolerance at flat plates.

Weight:

Plate production is done as appropriate to 5% tolerance in plate weight.

Length:

Plates are produced with +2,5/-2 cm tolerance for 0-5 meter, +5/-3 cm tolerance for 5-10 meters and +5/-3 cm tolerance for more than 10 meters according to customer demand. Regarding transportation conditions, corrugated plates can be produced up to 15 meters. Flat plates can be produced in demanded lengths as far as they are appropriate to form roller.

Packing:

Plates can be presented to market by packing or in bulk form. For packing customer’s demand is regarded and number of stacked plates is determined according to transportation conditions.

Width:

Final width of plates according to used profile is appropriate to the values determined in profile leafs unless a different demand comes from customer. Width tolerance is ±0,001 meter.

Pitch Interval:

Pitch intervals of plates are ± 2 mm as appropriate to used profiles and values in standards.

Pitch Height:

Pitch heights of plates are values appropriate to used profiles.

Pitch height tolerance:

±2 mm for <30 mm and ±3 mm for >30mm.

An increase in pitch heights + deviation values is normal when plate thickness increases (at thicknesses bigger from 3 mm).

Beneficial Area:

Beneficial areas of plates are values determined in their leaf. Tolerance is ±10 mm.

Label:

Labeling is done with inkjet system in order to follow after sales traceability.

» Flexible, light, resistant against shocks,

» CTP transparent sinus and trapeze corrugated plates are decorative,

» Provides natural illumination,

» Provides homogenous light distribution,

» Can be used alone,

» Can be used together with all roof materials,

» Is not affected from chemical materials,

» Can be produced with film coating for resistance against UV lights.

Thermal Resistance:

It has thermal resistance between -40 C and 120 C. It does not change shape with temperature as it is in Thermoset plastic group. Polyethylene sponges used in panels do not create thermal bridge.

Resistance and Weight Relationship:

With its property of light weight and high mechanic resistance, it is resistant against all air conditions (wind, hail etc.) and shocks.

Resistance Against Corrosion and Chemicals:

Resistant against chemicals and high temperature. It has long lifespan due to its anticorrosive feature.

Resistance Against Water:

It has very long life with its property of low water absorption and perfect water resistance.

Resistance Against UV Lights and Surface Aging:

It can be produced from special polyester with UV stabilization, it has UV and high surface resistance features with protective film, gelcoat applications.

Incombustibility:

It has inflammability feature with various performances appropriate to demand and needs.

Insulation:

Prevents high voltage arc with its insulation feature.

Easy Installation and Transportation:

As appropriate to many known application technique, it has advantages of easy installation and easy transportation because of its light weight.

Wide Profile Choices:

Provides possibility of production in all profiles and design flexibility due to its rich profile variety.

Day Light:

Provides natural light with daylight and energy saving with its 75-80% light transmittance.

» CTP transparent sinus and trapeze corrugated plates are decorative,

» Provides natural illumination,

» Provides homogenous light distribution,

» Can be used alone,

» Can be used together with all roof materials,

» Is not affected from chemical materials,

» Can be produced with film coating for resistance against UV lights.

Thermal Resistance:

It has thermal resistance between -40 C and 120 C. It does not change shape with temperature as it is in Thermoset plastic group. Polyethylene sponges used in panels do not create thermal bridge.

Resistance and Weight Relationship:

With its property of light weight and high mechanic resistance, it is resistant against all air conditions (wind, hail etc.) and shocks.

Resistance Against Corrosion and Chemicals:

Resistant against chemicals and high temperature. It has long lifespan due to its anticorrosive feature.

Resistance Against Water:

It has very long life with its property of low water absorption and perfect water resistance.

Resistance Against UV Lights and Surface Aging:

It can be produced from special polyester with UV stabilization, it has UV and high surface resistance features with protective film, gelcoat applications.

Incombustibility:

It has inflammability feature with various performances appropriate to demand and needs.

Insulation:

Prevents high voltage arc with its insulation feature.

Easy Installation and Transportation:

As appropriate to many known application technique, it has advantages of easy installation and easy transportation because of its light weight.

Wide Profile Choices:

Provides possibility of production in all profiles and design flexibility due to its rich profile variety.

Day Light:

Provides natural light with daylight and energy saving with its 75-80% light transmittance.

Usage Areas

» Industrial structures

» Houses

» Chemical production plants

» Nourishment plants

» Manure drying plants

» Sports centers

» Thermal swimming pools

» Touristic plants

» Greenhouses

» Agriculture and stock-breeding sector

» Market places

» Fair areas

» Arbors

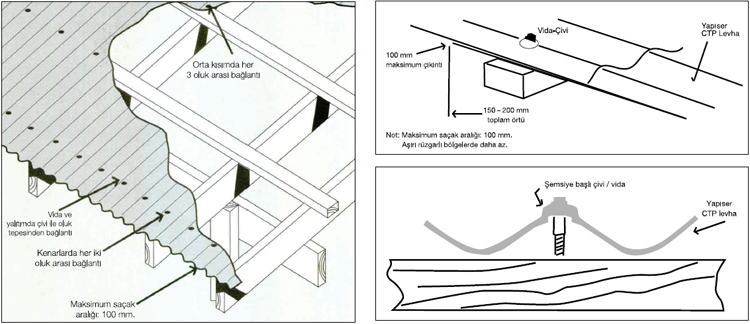

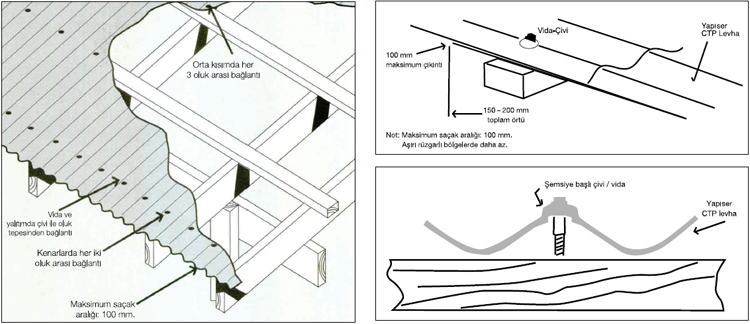

Application

Yapıser CTP plates can be applied to roofs as metal panels. Ordinary tools used for metal panels can be used for them too. They can be cut by electrical saw without any damage, they can be drilled, screwed and nailed by carpenter tools.

» Industrial structures

» Houses

» Chemical production plants

» Nourishment plants

» Manure drying plants

» Sports centers

» Thermal swimming pools

» Touristic plants

» Greenhouses

» Agriculture and stock-breeding sector

» Market places

» Fair areas

» Arbors

Application

Yapıser CTP plates can be applied to roofs as metal panels. Ordinary tools used for metal panels can be used for them too. They can be cut by electrical saw without any damage, they can be drilled, screwed and nailed by carpenter tools.

| CHEMICAL FEATURES | |

| Acid vapors | Not affected |

| Sea water | Not affected |

| Environmental pollution | Not affected |

| Natural Conditions | Not affected |

| PRODUCTION LIMITS | |

| Profile | Max. 10 days for all kinds of profiles |

| Length | Max. 10 m (can be longer according to order) |

| Thickness | Min. 0.9 mm. Max. 3 mm |

| Weight | Special production is possible by determining plate thickness |

| Color | Transparent, white, green, blue, yellow, red, orange |

| Light transmittance | Transparent 85%, transparent green 76%, white 57% |

| TECHNICAL SPECIFICATIONS | |

| Density | 1,4 gr/cm |

| Hardness | 40 Barcol |

| Water absorption rate | %(0,3-0,8) by weight |

| Light transmittance | %75-85 |

| Tensile strength | 720 kg/cm |

| Bending strength | 1200 kg/cm |

| Pressure strength | 1000 kg/cm |

| Flash Point | 404,4 °C |

| Thermal conductivity coefficient | 0,15-0,20 W/mK |

| Heat resistance | -40 °C -+120 °C |

| Expansion | 9-25 mm X 10-6 mm/ °C |

| Surface | With or without film |