Products

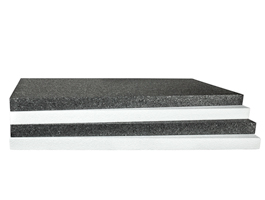

Yapıpor Board

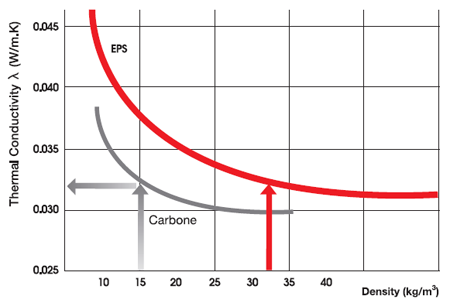

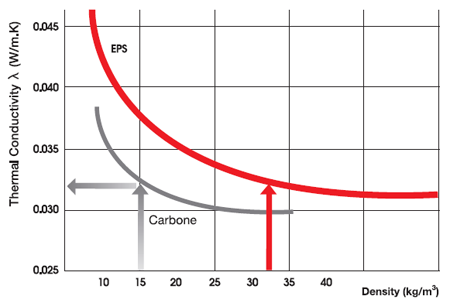

Yapıpor plates are standard plates produced in blocks and cut with resistance wires by heat in demanded thickness. Plates are produced in both EPS and carbon reinforced EPS forms. Heat insulation value of carbon reinforced products is %20 percent bigger than standard products. This product is preferred especially when thickness is functional. For example EPS plate which is used as 4 cm in standard product can be used as 3 cm with the same heat insulation value for the same area with carbon reinforced product.

Yapıpor white plates provide high heat insulation. Performance of product is constant during all usage life. Its thickness does not decrease, its thermal conductivity does not increase, its mechanic features does not change and other features does not decay by time.

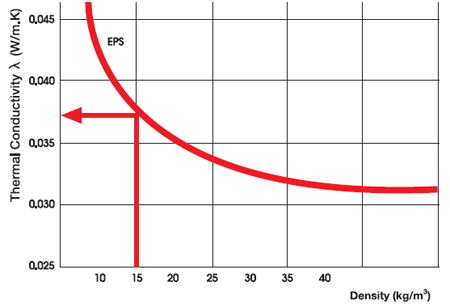

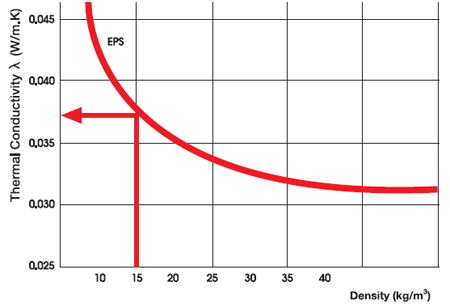

Thermal conductivity and heat resistance of EPS heat insulation plates stay constant during their lifespan. They can be produced in different densities. Thermal conductivity gets better when density increases.

It is light, durable and easily workable.

It is an easily recyclable product. It is also environmentally friendly as it does not damage atmosphere and ozone layer.

Important Issues

» Do not subject to direct sunlight during application and storage

» Do not contact with materials including solvent

» Keep away from flammable and explosive materials

» Keep away from all kinds of heat sources

λ = Thermal conductivity coefficient µ = Water vapor diffusion resistance factor

E class according to TS-EN 13501-1

Thermal conductivity and heat resistance of EPS heat insulation plates stay constant during their lifespan. They can be produced in different densities. Thermal conductivity gets better when density increases.

It is light, durable and easily workable.

It is an easily recyclable product. It is also environmentally friendly as it does not damage atmosphere and ozone layer.

| EPS TYPE | TS EN 13163 | UNIT | EPS 70 | EPS 100 |

| Thermal Conductivity | EN 12667 - EN 12939 | W/m.K | 0,039 | 0,035 |

| %10 Compression Strength | EN 826 | kPa | 70 | 120 |

| Bending Strength | EN 12089 | kPa | 100 | 170 |

| Dimensional Stability | EN 1603 | DS (N) 2 | ±0,2 | ±0,2 |

| Density | EN 1602 | kg / m3 | 16 | 20 |

Important Issues

» Do not subject to direct sunlight during application and storage

» Do not contact with materials including solvent

» Keep away from flammable and explosive materials

» Keep away from all kinds of heat sources

| Density (kg/m) | WidthxLength (cm) | Thickness (cm) | Number (Package) | m3 (Package) | Area ( m2) | (W/m.K) | µ |

| 16 | 50 x 100 | 2 | 25 | 0,25 | 12,5 | 0,032 | 20 - 40 |

| 3 | 16 | 0,24 | 8 | ||||

| 4 | 12 | 0,24 | 6 | ||||

| 5 | 10 | 0,25 | 5 | ||||

| 20 | 6 | 8 | 0,24 | 4 | 0,031 | 30 - 71 | |

| 7 | 7 | 245 | 3,5 | ||||

| 8 | 6 | 0,24 | 3 | ||||

| 9 | 5 | 0,225 | 2,5 | ||||

| 10 | 5 | 0,25 | 2,5 |

E class according to TS-EN 13501-1

Yapıpor carboniferous plates gain infrared absorbance and reflection characteristic due to graphite addition in its content and reduce heat resistance seriously. It also gains its color from this material. EPS with graphite addition has superior characteristics of EPS like superior specifications, water vapor impermeability, dimension stability, being environmentally friendly. EPS with graphite addition is produced appropriate to DIN EN 13163 European Standard conditions and according to DIN EN 13501 its fire class is classified under E. It provides a 20% better heat insulation than EPS plates and it will be possible to reach an insulation performance equal to thinner insulation plates.

Performance of product stays constant during the lifespan of product. Its thickness does not decrease, its thermal conductivity does not increase, its mechanic features does not change and other features does not decay by time.They can be produced in different densities. Thermal conductivity gets better when density increases.

It is light, durable and easily workable.

It is a recyclable product. It is environmentally friendly as it does not damage atmosphere and ozone layer.

Important Issues:

» Do not subject to direct sunlight during application and storage

» Do not contact with materials including solvent

» Keep away from flammable and explosive materials

» Keep away from all kinds of heat sources

λ = Thermal conductivity coefficient µ = Water vapor diffusion resistance factor

E class according to TS-EN 13501-1

Performance of product stays constant during the lifespan of product. Its thickness does not decrease, its thermal conductivity does not increase, its mechanic features does not change and other features does not decay by time.They can be produced in different densities. Thermal conductivity gets better when density increases.

It is light, durable and easily workable.

It is a recyclable product. It is environmentally friendly as it does not damage atmosphere and ozone layer.

| EPS TYPE | TS EN 13163 | UNIT | EPS 60 | EPS 90 |

| Thermal Conductivity | EN12667 - EN112939 | λ W/m.K | 0,032 | 0,031 |

|

%10 Compression Strength |

EN 826 | kPa | 60 | 90 |

|

Bending Strength |

EN 12089 | kPa | 90 | 125 |

|

Dimensional Stability |

EN1603 | DS(N) 2 | ± 0,2 | ± 0,2 |

| Density | EN 1602 | kg / m3 | 16 | 20 |

Important Issues:

» Do not subject to direct sunlight during application and storage

» Do not contact with materials including solvent

» Keep away from flammable and explosive materials

» Keep away from all kinds of heat sources

| Density (kg/m) | WidthxLength (cm) | Thickness (cm) | Number (Package) | m3 (Package) | Area ( m2) | λ (W/m.K) | µ |

| 16 | 50 x 100 | 2 | 25 | 0,25 | 12,5 | 0,032 | 20 - 40 |

| 3 | 16 | 0,24 | 8 | ||||

| 4 | 12 | 0,24 | 6 | ||||

| 5 | 10 | 0,25 | 5 | ||||

| 20 | 6 | 8 | 0,24 | 4 | 0,031 | 30 - 71 | |

| 7 | 7 | 245 | 3,5 | ||||

| 8 | 6 | 0,24 | 3 | ||||

| 9 | 5 | 0,225 | 2,5 | ||||

| 10 | 5 | 0,25 | 2,5 |

E class according to TS-EN 13501-1

» Exterior walls

» Cold stores

» Commercial fridges

» Vehicles with cooling systems

» Decoration works

» Cold stores

» Commercial fridges

» Vehicles with cooling systems

» Decoration works